Our custom die-cutting services are designed to meet your specific requirements and ensuring optimum performance and efficiency.

— Converting, die-cutting and our offer

Custom

die-cutting services

Unrivalled accuracy with every cut

At the company OLEJÁR, we specialize in custom die-cutting services that offer unparalleled accuracy and adaptability to meet the unique needs of each project. Our die-cutting services are renowned for their accuracy. We are able to deal with complex designs and intricate shapes, ensuring that every part meets strict quality and tolerance standards.

— Categories of die-cutting

We offer the following

types of die-cutting

We have available advanced rotary, flat and laser die-cutting technologies. Our versatility allows us to offer customized solutions for a wide range of materials including foams, adhesives, plastics and others. Our advanced engineering team is capable to assist you with the design of manufacturability, with selection of materials, cost vs. benefit analysis, and much more.

— Cutting technology

Converting

Contouring cut-outs production

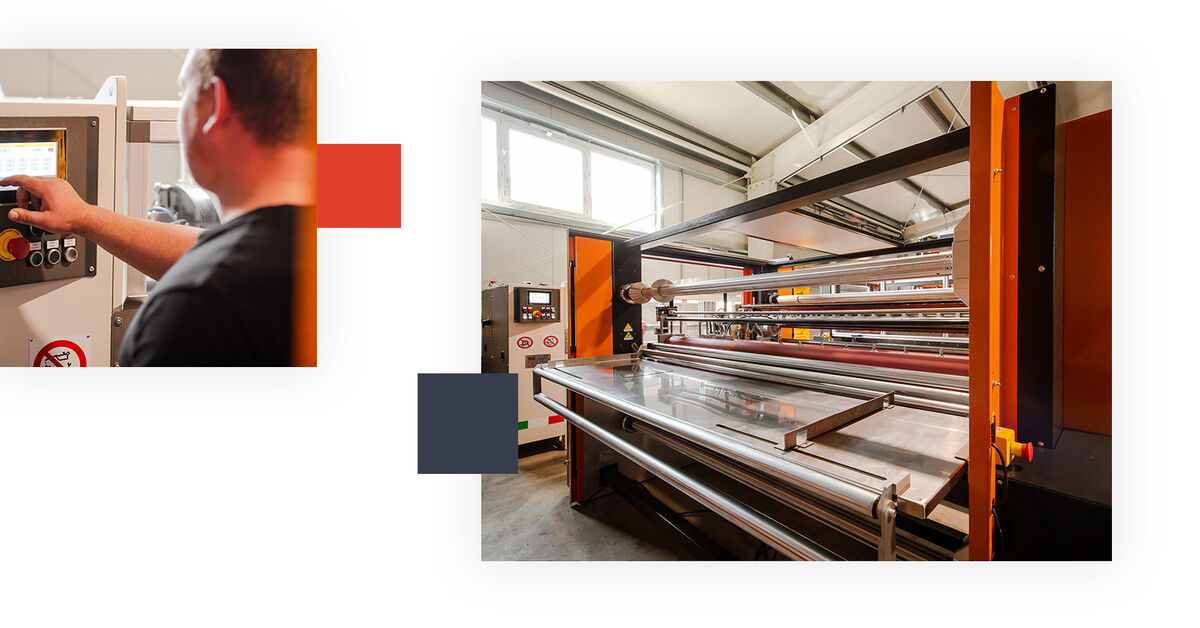

Processing of materials is performed via cutting technology with strict dimensions, die-cutting, kiss-cutting, rewinding and laminating with a variety of materials. The desired shapes can be supplied as individual pieces, in sheets or in rolls. Our machines are servo-driven, ensuring that we achieve excellent dimensional accuracy when die-cutting multilayer laminates or printed products.

— Die-cutting technology

Die-cutting

Precision cutting of materials

Die-cutting is the process of a precise cutting of materials into different shapes and sizes. It is used in a wide range of industries. Die-cutting involves cutting through the material itself as well as the its covering layer. The cut-outs are supplied as individual pieces and are used as seals, stops or semi-finished products for further processing.

Die-cutting is an essential tool for creating of original designs and products, and within modern technology it plays an important role in the modern industry and design.

— Kiss-cutting technology

Kiss-cutting

Cutting materials with a backing layer

This is a type of cutting in which the blade does not cut through the entire stack of material, but cuts through a precise number of layers. After die-cutting finished products remain in the roll or sheet, making it very easy to peel the die-cut from the backing layer.

Its flexibility and precision make this technology an essential part of modern industry. It enables precise cutting of flexible materials (foam tapes, rubber, laminates) and adhesives and clean cutting of even the smallest details - holes, slots, apertures.

— Longitudinal cutting

Lamination

Application of laminating adhesive

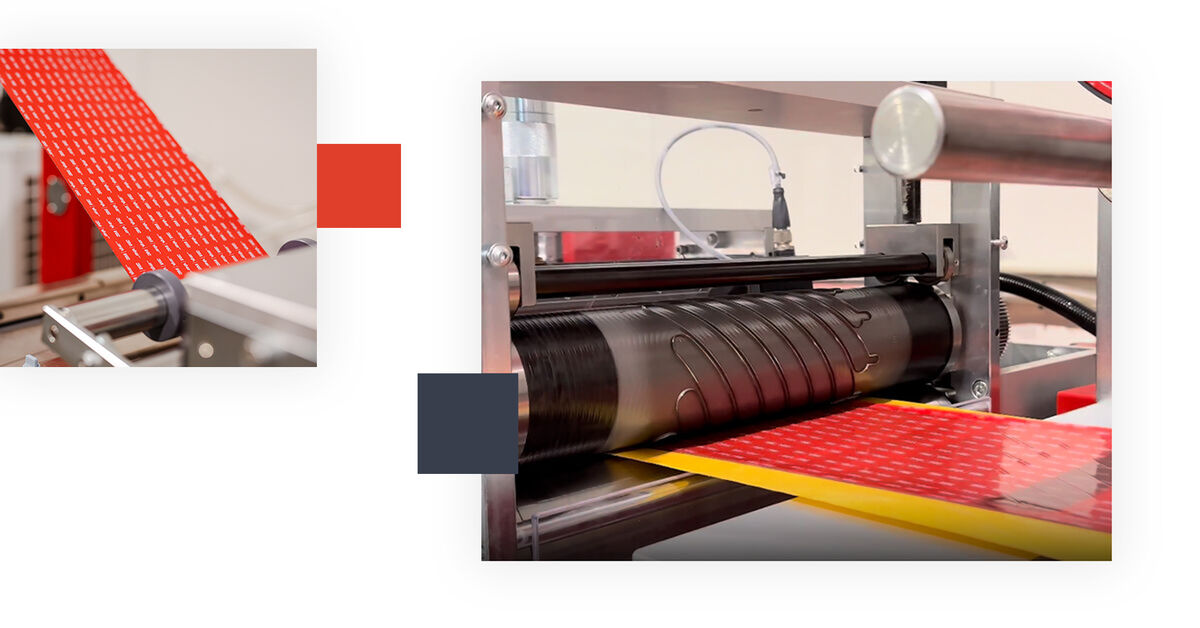

Lamination is a process in which we apply laminating adhesive to various types of non-adhesive materials using a laminator in order to make the materials sticky. Thanks to our variable machinery we can laminate single pieces (plates) as well as roll formats.

We offer cutting and laminating of various materials such as: c covering and synthetic materials, textiles, rubber, PVC foils, polyethylene, polyurethane, non-woven fabrics, graphite. Lamination may be done single-sided or double-sided.

— Slitting technology

Cutting of logrolls

Cutting of adhesive tapes in a roll

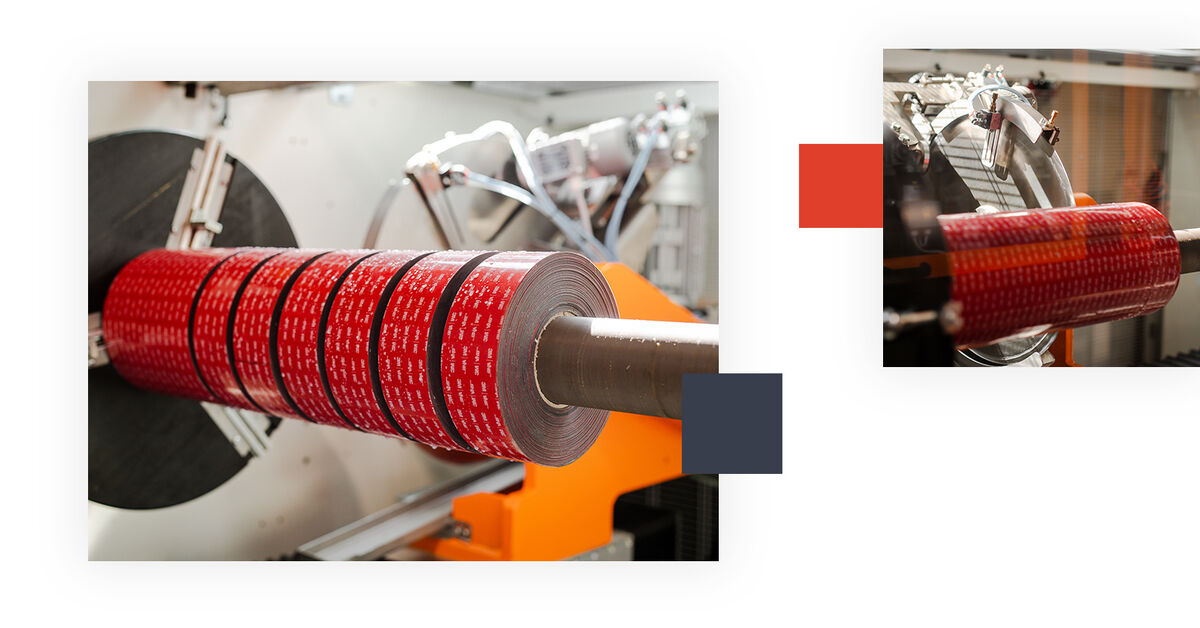

As part of our services, we offer machine cutting of materials, which allows customers to obtain precisely defined dimensions of adhesive tapes and other products. This process, known as "slitting", takes is performed with our special machine that can cut rolls of material with incredible precision.

The cutting of the strips is carried out from already produced logrolls of different widths and winding lengths on special machines with one or more knives. Each piece of our products must comply with customer's specifications and requirements.

— Top cutting plotters

Cutting with a plotter

Unlimited opportunities for different industries

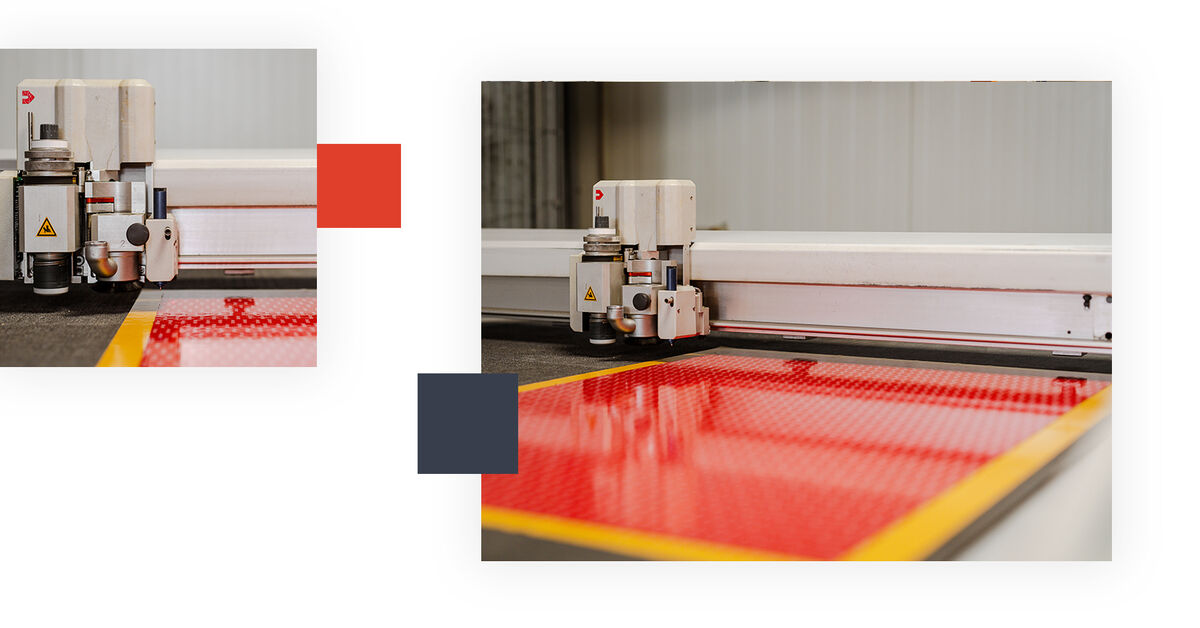

Plotter cutting is the process of using a cutting plotter to create different shapes and inscriptions from self-adhesive film or other materials. This process is used to produce advertising stickers, signs, graphics and other design elements.

Plotter cutting allows for the production of complex shapes and flexibility in the production of patterns and small batches of die-cuts where a cutting tool is not required. We can cut shapes up to 1500 x 1200 mm.

— Laser power 350W

Rotary laser cutter 350 MM

Rotary kiss-cutting and die-cutting in combination with laser

Kiss-cutting - laser die-cutting, which meets the needs of critical applications, enables precision cutting of flexible materials (foam tapes, rubber, laminates) and adhesives. The highly repeatable process allows precise and clean cutting of the smallest details - holes, slots, apertures.

Although kiss-cutting is often associated with rotary die-cutting, however, the kiss-cutting can also be made using a laser, which can be applied for kiss-cuts in the material by regulating the laser power frequency, so it does not cut through the entire layer of material, but only a certain thickness in accordance with the requirements.

Laser cutting is well-known for its precision and it can deal with complex shapes, ensuring that each part will meets strict quality standards and tolerances adapted to your industry. Our custom die-cutting services are designed to meet your specific requirements and they ensure optimum quality and efficiency.

The digital laser die-cutting and converting system offers the greatest flexibility and production capacity for materials up to 350 mm wide. Depending on the application, laser cutting can reach speeds of up to 100 meters per minute.

Laser cutting and converting system offers innovative and cost-effective solutions for processing of simple and complex geometries without traditional hard tooling - superior quality of parts that cannot be achieved with the traditional die-cutting process.